Wire Harness Manufacturing Process

Home / Manufacturing Process

Step1. Check Specifications

After receiving the order through the e-commerce system, we will

confirm it according to the drawings and specifications you provided.

If there are items to be confirmed, we will contact you and resolve

questions before the manufacturing process.

Step1. Check Specifications

Step2. Wire (Cable) Cutting

Cut the wire (cable) to the required length and roll it hollow. The

workers check the specifications carefully recorded in the production

order before cutting the wire, and use calibrated equipment to ensure

processing quality.

Step2. Wire (Cable) Cutting

Step3. Cable Preprocessing

This is the process of removing the coating and unused filler from the wire.

JetHarness will use professional wire stripping machine to peel off the

covering, including the outer wire covering and the inner core wire

covering. After completion proceed to the welding process.

A wire consists of a conductor core and an insulating coating. In order for

it to conduct electricity, the coating must be peeled off.

During this process, the machine is adjusted according to each wire

specification so that there are no cuts or scratches on the core conductor

before proceeding to the next stage.

Step3. Cable Preprocessing

Step4. Crimping

This is the process of crimping the terminals and wire (cable) core

conductors together. Use a professional terminal crimping machine

to complete.

Different terminals use different crimping dies, so the operator must

ask a professional to adjust the machine and check the specifications

in advance.

Step4. Crimping

Step5. Assembly and Processing

This is a very important stage in the production process. Classify the core

wires of the crimped terminals according to the engineering drawing and

assemble them into the connector body.

The strength of the wire harness is also strengthened in the process.

After crimping (or welding) the core wires and terminals, the wires (cables)

are assembled into the connector shell. All production is performed

according to the engineering drawings and SOP records, and special tools

are used.

Step5. Assembly and Processing

Step6. Label

Put on labels with specifications, ID, and S/N content

(the content is provided by the customer or JetHarness) to each

customized wire. This label can help the installation quickly

find the contact, and also facilitates the search for production history

in the future.

Step6. Label

Step7. Appearance Inspection

Wire harness inspections based on the drawings and dimensions of the

production order to ensure that the relevant production details are correct.

Step7. Appearance Inspection

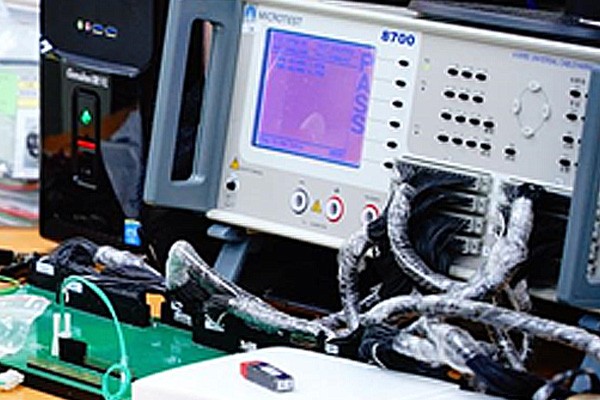

Step8. Electrical Characteristics Test

All completed wire harnesses will be connected to a four-wire

electrical testing machine with corresponding electrical testing

fixtures for continuity, short/open circuit, resistance, pinout,

insulation high-pot, etc.

All wire harnesses have gone through the process of electrical

characteristics testing to confirm quality and reliability.

Step8. Electrical Characteristics Test

Step9. Finished product quality control & image recording

This is the process of video recording and storing the finished wire harness.

Digitally archive production engineering data, making it easier to discuss,

review, create, add new modifications, or query later. System management

and digital database can accurately re-manufacture wire harnesses with

the same specifications and ensure the same quality.

Step9. Finished product quality control & image recording

Step10. Packaging/Shipping

This is the process of packaging and shipping the finished product.

Use cushioning packaging to prevent damage to the product during

transportation, and transport it according to the designated method.

Arrival date depends on destination and shipping method.

Step10. Packaging/Shipping

The manufacturing method of the wire harness is explained using general products.

The actual production process of each customized wire harness may be different.

New Visitor

Manufacturing Production

Safety Instructions

About Us

Terms of Service

© 2022 Jet Harness

Design by NSS Group