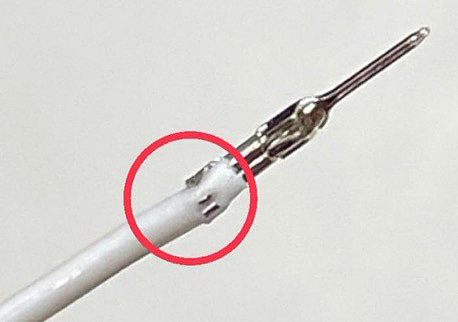

Poor manual terminal crimping processing

- News

Terminals are a common electronic material and are important connectors used to connect wires and electrical equipment.

It connects the two ends of the wire together to form a firm and reliable connection point, ensuring the stable transmission of power and electrical signals.

●Terminal connection method

There are several ways to connect the terminal to the wire core, including crimping, welding, etc. It is one of the most important processes in wire harness processing.

A good termination, in addition to having the correct terminals, must also be equipped with conductors of appropriate thickness to withstand physical damage such as high temperature and high vibration, and have excellent electrical performance in harsh environments.

Crimping: Use terminal crimping pliers to terminate the wire and terminal and make them fit tightly together.

Advantage:

●No need to heat or use solder, gas, chemicals, etc..

●Fast and convenient, providing excellent conductivity and safety.

Disadvantages:

●The crimping is not in place, resulting in uneven core wires and insufficient clamping force, which in turn affects the electrical connection and is prone to rust and corrosion, resulting in increased impedance.

●If the crimping is too tight, the wire may become fragile, the wire strength may be reduced and it may be easily broken, or the cross-sectional area of the joint may become smaller and the resistance may increase, causing the temperature at that location to rise.

(Poor processing of manual crimping terminals)

Soldering: A technique for joining metals by melting solder using heat.

Advantages:

●Provide stable electrical connection to maintain good performance.

●Easy to maintain and replace.

Disadvantages:

●High temperature welding may cause the insulation layer of the wire to deform, affecting performance

●Operators must have certain skills and knowledge to ensure quality.

(Soldering)

二、JetHarness Wire Harness Processing Quality

JetHarness uses automated equipment for crimping, which has fast processing speed and high accuracy.

It is produced with special molds. The clamping and covering at both ends can be evenly symmetrical, which improves the clamping force of the core wire.

Non-personnel use of hand tools can avoid poor quality during terminal processing.

(Automation equipment crimping terminals)

New Visitor

Manufacturing Production

Safety Instructions

About Us

Terms of Service

© 2022 Jet Harness

Design by NSS Group