M8 and M12 circular connectors: technical spec, applications, categories, and selection tips

- Latest news

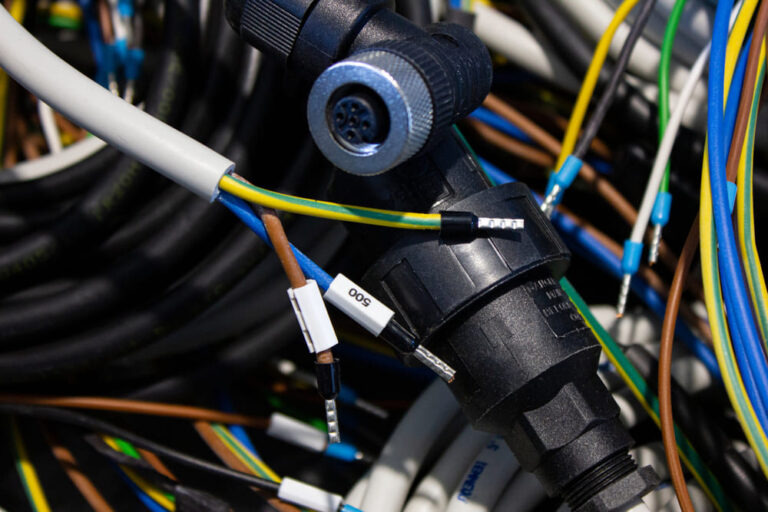

With the popularization of electronic devices and industrial automation, standard circular connectors have become an important connection tool between devices, but did you know that the appropriate circular connectors will vary depending on the environment?

This article will focus on the common M8 and M12 circular connectors, and will show you their specifications, features, and tips for selecting circular connectors.

Let’s learn more about them together!

M8, M12 circular connector technical specifications, features

The M-type standard circular connector, which is widely used in industrial networks, can actually be further divided into M5, M8, M12, M17, M23, M40, etc., where “M” represents the metric thread size on the coupling nut and the mating socket, such as M5 is 5mm, M8 is 8mm, and so on.

The following will first introduce the specifications and features of common M8 and M12 connectors.

1.M8 circular connector

The M8 circular connector, which is only 8mm in diameter, has a high dust and water resistance rating of IP67 or IP68, making it very suitable for small spaces.

Therefore, it is widely used in sensors, robotic arms, medical equipment, and marine electronic equipment, which have limited space and need to cope with humid or dusty environments.

In addition, the M8 circular connector provides 3, 4, 5, 6 and 8-pin pin contact configurations, with a variety of connection methods such as welding and screw locking.

It is not only easy to install on site, but also can meet the needs of high-speed data transmission, greatly improving its reliability and shock resistance, and ensuring that the connection process will not be interfered with by external factors.

2.M12 circular connector

M12 is the most common circular connector option and has many advantages, including protection against electromagnetic interference, protection levels between IP67 and IP69K, durability, and multiple uses such as signals, power, and networks.

Therefore, it is widely used in different industries such as automobiles, renewable resources, process control, medical equipment, and food and beverage.

Even in harsh manufacturing environments or corrosive environments, the M12 circular connector has strong adaptability and can ensure high-performance transmission of various signals and data, allowing equipment to achieve higher productivity!

M8 and M12 connector specifications can also be subdivided into these categories!

Depending on the mechanical structure, foolproof design and application requirements, circular connectors can be subdivided into different codes to define the number of cores, contact body shape, etc., and ensure correct connection.

For example, the M8 circular connector includes A, B, and K codes; the M12 has a wider range, including A, B, C, D, K, L, M, P, S, T, X and other codes.

The following explains several common coding uses:

- A code: The most common circular connector coding, mainly used for signal, data transmission and most standard equipment, such as motors, standard 24V DC, standard sensor signal interface, 1 Gbit Ethernet, etc.

- B code:Connects DC signals and is mainly used for network cables connected to field buses, such as Profibus and Interbus.

- C code:Designed for alternating current, such as standard 24V/110V/230V AC, and has a double lock hole design for added security to prevent accidental connection.

- D code:Suitable for industrial Ethernet communications, Profinet, Ethernet/IP, EtherCat and other applications, and can transmit up to 100Mb of data.

- S code:For AC power connection, rated voltage up to 630V, maximum current per pole 12A, usually available in 3-pole (2+PE) or 4-pole (3+PE) versions, and can be used as a substitute for C-coded parts.

- T code:esigned for DC power supplies, it can be used as a substitute for A-coded parts, with a rated voltage of up to 63VDC/AC and a rated current of 12A per pole.

- X code:Designed for high-speed data transmission, it is particularly suitable for Gigabit Ethernet applications and can support data transmission rates up to 10 Gbps.

With so many circular connector options, how do you choose?

1. Consider the application environment

Circular connectors can be widely used in military, aerospace, industrial machinery, railways, audio engineering and radio communications.

Whether facing extreme environments such as vibration, shock, temperature and pressure, or environments that require high levels of electromagnetic interference (EMI) and radio frequency interference (RFI) protection, we can provide corresponding solutions!

For example, in applications that require waterproofing and dustproofing, the M8 waterproof connector is an ideal choice because it has an IP67 or IP68 protection level and can operate stably in underwater and dusty environments.

2.Technical specifications match

Ensuring that the technical specifications match the equipment is the most important key to selecting circular connectors.

Whether it is the connector size, number of pins or voltage and current capacity, they cannot be ignored.

It is also recommended that the male and female sockets be purchased in pairs to avoid incompatibility issues caused by specification differences due to different suppliers.

If you are not sure how to choose, the International Electrotechnical Commission provides the IEC-61076-2 technical specification.

Whether it is mechanical structure size or electrical characteristics requirements, you can get standard reference in this document.

3.Ease of use and durability

If the circular connector needs to be frequently plugged in and out, then choosing a sturdy and durable material becomes the key.

For example, tough metal materials, combined with a plating surface with good signal conductivity, will improve overall durability.

Secondly, the installation position of the circular connector is also very important.

For example, panel-mounted circular connectors are suitable for use with fixed slots and jacks; cable installation is more suitable for flexible application scenarios.

Users can choose suitable products from circular connectors of various sizes from M5 to M40 according to actual needs, including signal transmission, power transmission or mixed transmission, so as to ensure reliable operation in various environments.

In conclusion

When choosing a suitable circular connector, you need to consider everything from technical specifications, application environment to installation methods!

JetHarness has more than 20 years of professional production experience, owns a 10,000-level clean room, and has obtained multiple standard certifications.

It is committed to providing high-quality, durable and versatile connectors, including M8 and M12 circular connectors.

If you have customized needs, welcome to contact JetHarness for customized circular connectors.

We not only have no minimum order quantity limit, but also can freely change the length of cable assemblies and deliver quickly.

We are your most trustworthy and development choice!

New Visitor

Manufacturing Production

Safety Instructions

About Us

Terms of Service

© 2022 Jet Harness

Design by NSS Group